In IIoT infrastructures, sometimes can be challenging to extract and contextualize data from from various systems into the Unified Namespace, because there is no universal solution. It usually requires lots of different tools, each one tailored to the specific infrastructure, making it hard to manage and maintain.

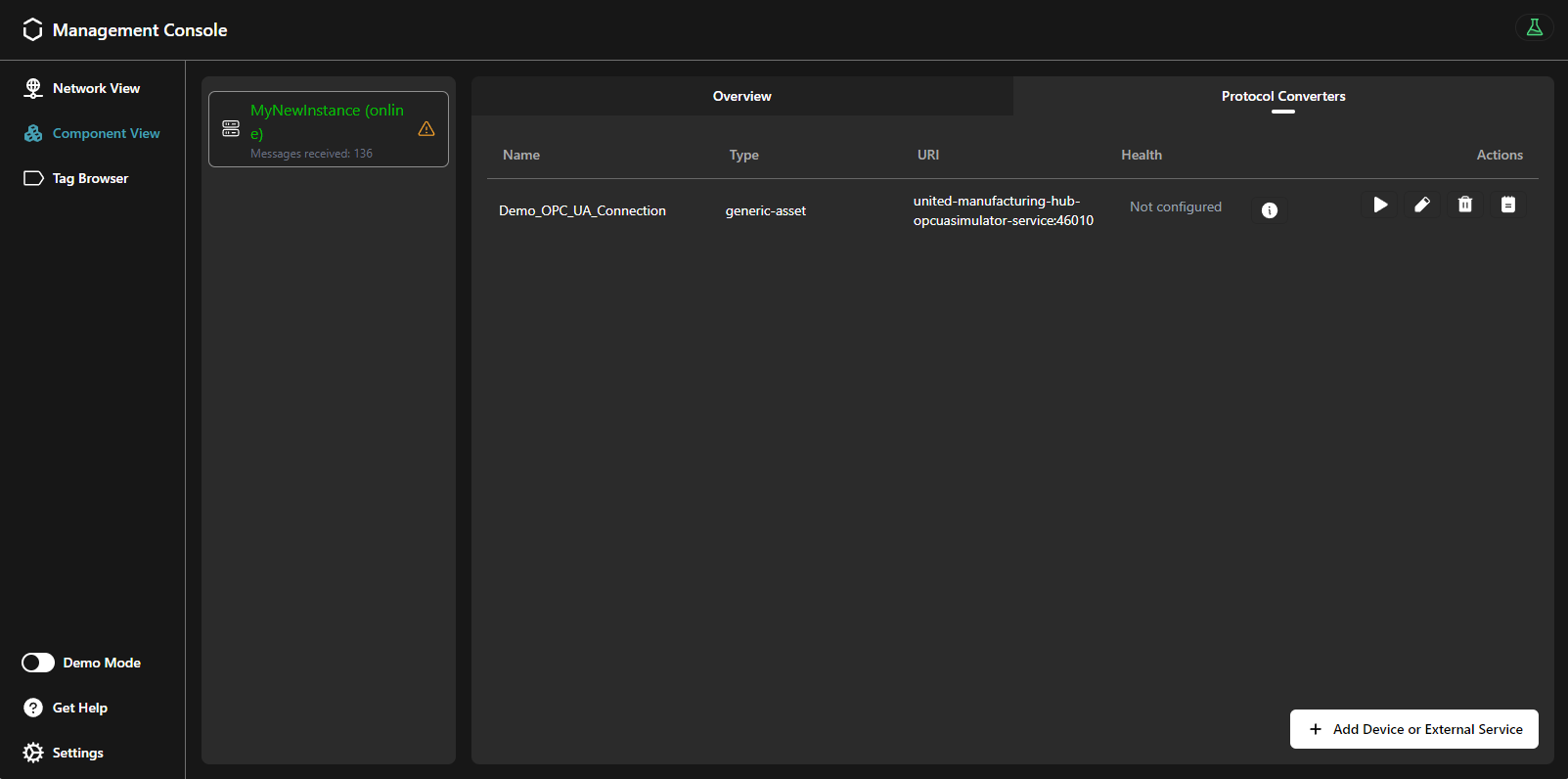

With the United Manufacturing Hub and the Management Console, we aim to solve this problem by providing a simple and easy to use tool to manage all the assets in your factory.

For lack of a better term, when talking about a system that can be connected to and that provides data, we will use the term asset.

When should I use it?

Contextualizing data can present a variety of challenges, both technical and at the organization level. The Connection Management functionality aims to reduce the complexity that comes with these challenges.

Here are some common issues that can be solved with the Connection Management:

- It is hard to get an overview of all the data sources and their connections' status, as the concepts of “connection” and “data source” are often decoupled. This leads to list the connections’ information into long spreadsheets, which are hard to maintain and troubleshoot.

- Handling uncommon communication protocols.

- Dealing with non-standard connections, like a 4-20 mA sensor or a USB-connected barcode reader.

- Advanced IT tools like Apache Spark or Apache Flink may be challenging for OT personnel who have crucial domain knowledge.

- Traditional OT tools often struggle in modern IT environments, lacking features like Docker compatibility, monitoring, automated backups, or high availability.

What can I do with it?

The Connection Management functionality in the Management Console aims to address those challenges by providing a simple and easy to use tool to manage all the assets in your factory.

You can add, delete, and most importantly, visualize the status of all your connections in a single place. For example, a periodic check is performed to measure the latency of each connection, and the status of the connection is displayed in the Management Console.

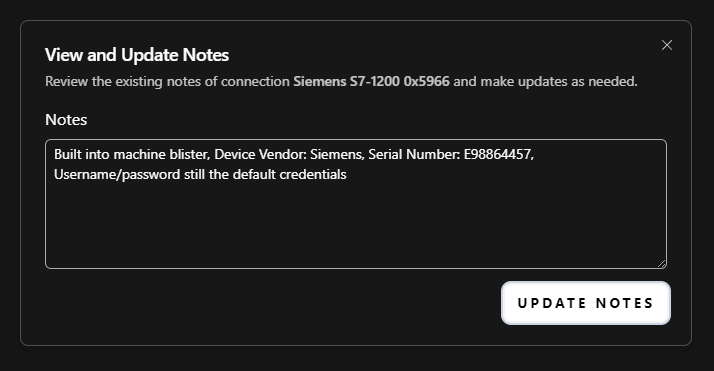

You can also add notes to each connection, so that you can keep all the documentation in a single place.

You can then configure a data source for each connection, to start extracting data from your assets. Once the data source is configured, specific information about its status is displayed, prompting you in case of misconfigurations, data not being received, or other any error that may occur.

How can I use it?

Add new connections from the Connection Management page of the Management Console. Then, configure a data source for each of them by choosing one of the available tools, depending on the type of connection.

The following tools come with the United Manufacturing Hub and are recommended for extracting data from your assets:

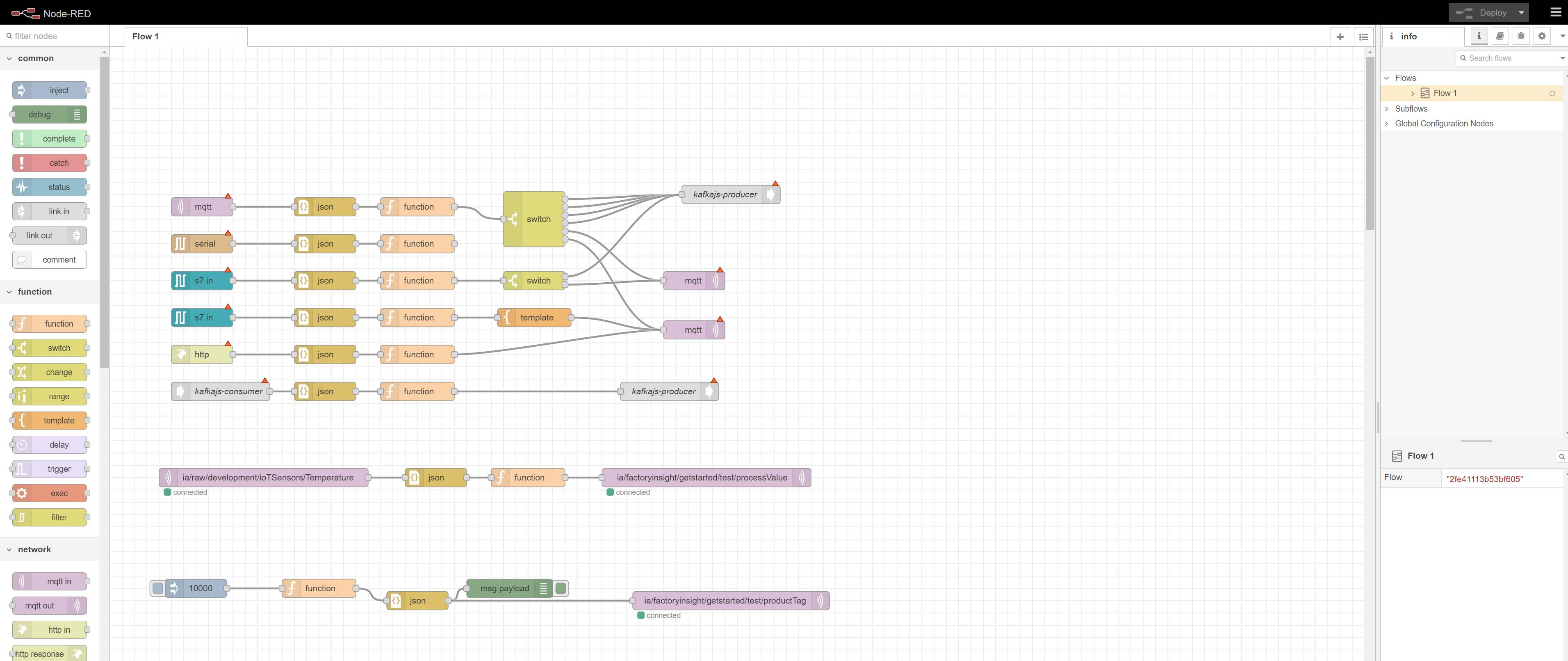

Node-RED

Node-RED is a leading open-source tool for IIoT connectivity. We recommend this tool for prototyping and integrating parts of the shop floor that demand high levels of customization and domain knowledge.

Even though it may be unreliable in high-throughput scenarios, it has a vast global community that provides a wide range of connectors for different protocols and data sources, while remaining very user-friendly with its visual programming approach.

Benthos UMH

Benthos UMH is a custom extension of the Benthos project. It allows you to connect assets that communicate via the OPC UA protocol, and it is recommended for scenarios involving the extraction of large data volumes in a standardized format.

It is a lightweight, open-source tool that is easy to deploy and manage. It is ideal for moving medium-sized data volumes more reliably then Node-RED, but it requires some technical knowledge.

Other Tools

The United Manufacturing Hub also provides tools for connecting data sources that uses other types of connections. For example, you can easily connect ifm IO-Link sensors or USB barcode readers.

Third-Party Tools

Any existing connectivity solution can be integrated with the United Manufacturing Hub, assuming it can send data to either MQTT or Kafka. Additionally, if you want to deploy those tools on the Device & Container Infrastructure, they must be available as a Docker container (developed with best-practices). Therefore, we recommend using the tools mentioned above, as they are the most tested and reliable.

What are the limitations?

Some of the tools still require some technical knowledge to be used. We are working on improving the user experience and documentation to make them more accessible.

Where to get more information?

- Follow the Get started guide to learn how to connect your assets to the United Manufacturing Hub.

- Deep dive into the Node-RED features.

- Explore retrofitting with ifm IO-Link master and sensorconnect.

- Learn how to retrofit with USB barcodereader.